Class II biosafety cabinets are divided into four types, A1, A2, B1 and B2, according to the proportion of discharge air to the total flow of the system and the internal design structure.

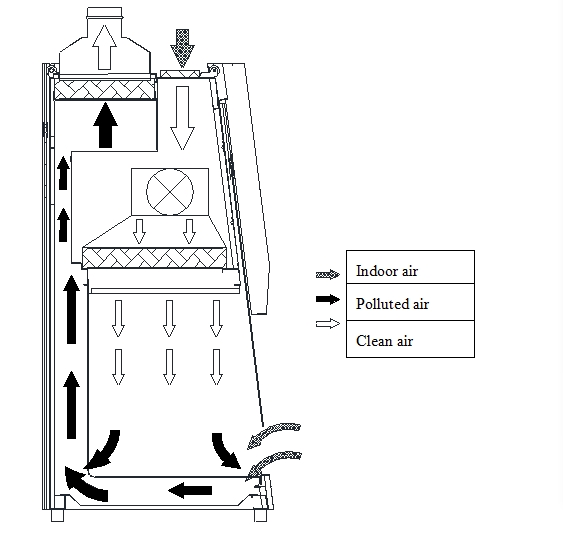

A1 type safety cabinet front window airflow velocity minimum or measured average should be at least 0.4m/s. 70% of the gas in the safety cabinet is filtered through the HEPA filter and then recirculated to the working area, and 30% of the gas is discharged through the HEPA filter at the exhaust port. The polluted air in the safety cabinet can be discharged to the laboratory or to the atmosphere through the exhaust pipe through the exhaust interface of the safety cabinet after being filtered by the high efficiency air filter.

A2 type safety cabinet front window airflow velocity minimum or measured average should be at least 0.5m/s. 70% of the gas is recirculated to the working area through the HEPA filter, and 30% is filtered out through the exhaust port. The polluted air in the safety cabinet can be discharged to the laboratory or to the atmosphere through the exhaust pipe through the exhaust interface of the safety cabinet after being filtered by the high efficiency air filter. The negative pressure of the safety cabinet is designed around the contaminated area to prevent the leakage of substances in the cabinet.

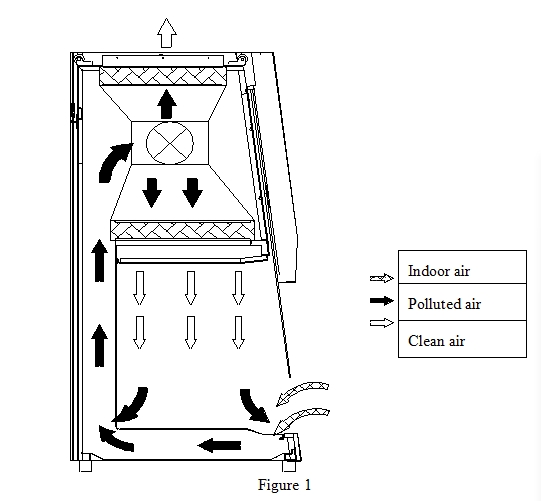

The minimum flow rate of the incoming air flow at the front window of the B1 type biosafety cabinet is 0.50m/s.30% of the gas in the cabinet is filtered through the high efficiency air filter and recycled, and 70% of the gas is filtered through the exhaust port HEPA filter and discharged into the atmosphere through the special air duct. All bio-contaminated sites should maintain negative pressure or be surrounded by negative pressure channels and negative pressure ventilation systems.

The minimum flow rate of the inflow air flow at the operating port of the front window of the B2 type biosafety cabinet is 0.5m/s, and the downdraft in the cabinet is all supplied by the outside of the cabinet, that is, the gas discharged from the safety cabinet is no longer recycled. The air flow in the cabinet is filtered into the atmosphere and is not allowed to enter the safety cabinet for circulation or backflow back to the laboratory, which can provide biological and chemical safety control at the same time. All contaminated parts should be in a state of negative pressure or surrounded by negative pressure areas.