The working principle of the biosafety cabinet is mainly to pump the air inside the cabinet outwards, so that the cabinet maintains a negative pressure state, and protects the staff through vertical airflow; The outside air is filtered by the high efficiency air filter into the safety cabinet to avoid contamination of the treated sample; The air in the cabinet also needs to be filtered by HEPA filters before being discharged into the atmosphere to protect the environment. Therefore, there are certain requirements for the installation position of the biosafety cabinet in the verification of the biosafety cabinet.

※The safety cabinet environment should meet the requirements of BSL-1 to BSL-3 biological laboratories, maintaining the corresponding constant temperature and humidity conditions and cleanliness;

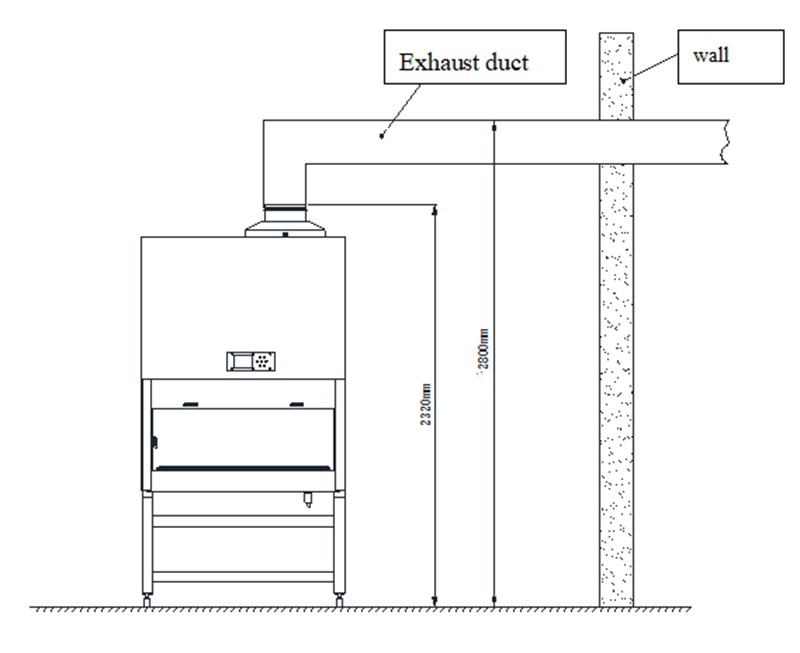

※The height of the room should not be less than 2.8m;

※The room area of a single instrument should not be less than 15㎡;

※Laboratory air supply: BSC-1060B2 shall be between 1150-1250 m3/h, and BSC-1360B2 shall be between 1550-1650m3/h.

※Ambient temperature: 10℃ ~ 30℃, relative humidity: ≤70% (25℃);

※Power supply: AC 220V, 50/60Hz, external power socket capacity should be greater than 16A;

※When used for microbial experiments with trace volatile toxic chemicals and trace radionuclides as auxiliary agents, the laboratory must have an exhaust system when installed, which is also a necessary condition for BSL-3 or above grade laboratory;

※The biosafety cabinet should be installed in the laboratory where people move less and are far away from the door, and the exhaust vent on the top of the safety cabinet should be far away from the laboratory exhaust system, so as to avoid the impact of large air flow fluctuations on the equipment.There should be no vent directly above the exhaust filter of the biosafety cabinet and above the operation port of the front window. If it cannot be avoided, a barrier plate should be installed to avoid the impact on the airflow of the biosafety cabinet.

※The installation position of the biosafety cabinet should be determined in accordance with the operation process. There should be a fixed power socket and liquid gas pipe interface nearby. The laboratory height should ensure that the upper part of the highest position of the safety cabinet is at least 400mm away from the external exhaust fan to ensure smooth exhaust. The distance between the fan and the safety cabinet must not be greater than 4 meters; otherwise, pipes and exhaust devices need to be added to ensure the ventilation capacity of the safety cabinet.

※Holes with a diameter of about Ф260~Ф 270 shall be drilled on the external walls with a height greater than 2800mm (either the rear or side external walls of the safety cabinet can be used as the exhaust pipe outlet.

※When installing the external exhaust system, ensure that the exhaust air is smooth; otherwise, the wind speed may be abnormal. In order to extend the service life of the exhaust fan, it is recommended that the user best install the exhaust fan under the awning, or the platform is directly fixed.

※For use at high altitudes, the wind speed must be recalibrated after installation.